Your cart is currently empty!

Space Manufacturin Taks Flicht: Glesga Researchers Pioneer 3D Printin in Zero Gravity

Space Manufacturin Taks Flicht: Glesga Researchers Pioneer 3D Printin in Zero Gravity

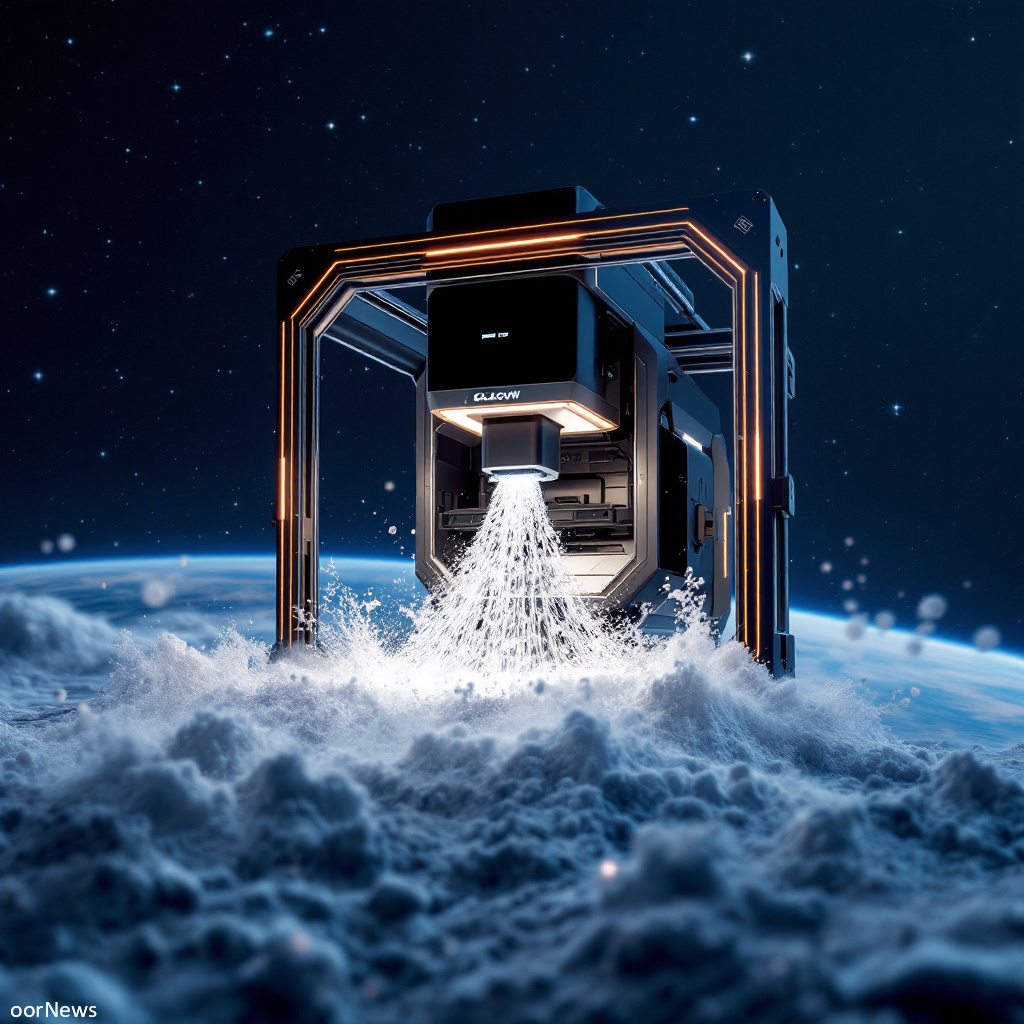

In a grundbrakkin leap for space exploration, researchers fae the University o Glesga’s James Watt School o Engineerin hae made significant strides tae the development o orbital factories capable o 3D printin technology on demand in space. Dr. Gilles Bailet has bin awarded a patent for an innovative system that tackles the challenges o 3D printin in zero-gravity environments. This technology wis rigorously tested aboard the research aircraft kent as the ‘vomit comet,’ whit simulates microgravity conditions.

Dr. Bailet emphasises that owercomin the hurdles o 3D printin in law-gravity cuid revolutionise hoo we manufacture equipment in orbit. This cuid lead tae the creation o solar reflectors for zero-carbon pouer generation, advanced communication antennae, an even drug research stations capable o producin purer pharmaceuticals.

For years, Dr. Bailet has focused on developin a prototype 3D printer tailored for ooter space. Unlike conventional printers that rely on filaments, his design yaises a specially developed granular material that performs effectively in the vacuum o space. This unique material can be drawn fae a feedstock tank an delivered tae the printer’s nozzle mair efficiently than traditional methods.

The research team is investigatin weys tae embed electronics intae the printed materials, pavin the wey for functional components in devices created in space. Dr. Bailet explains, “Currently, awthing that gaes intae Earth’s orbit is biggit on the surface an sent intae space on rockets. These rockets hae strict wecht limits an can damage cargo durin launch. If we cuid establish fabricators in space, we wid eliminate these constraints, allouin for mair ambitious projects.”

The recent tests conducted durin the 85th European Space Agency parabolic flicht campaign demonstrated the prototype’s effectiveness in microgravity. The team monitored the printer’s dynamics an pouer consumption durin 22-second wechtless intervals, confirmatin that the system performed as designed.

Dr. Bailet is optimistic aboot the future, statin, “We’ve tested the technology extensively in the lab an noo in microgravity. We’re confident it’s ready tae produce antennae an ither spacecraft pairts in space.” He pynts oot the potential for 3D-printed space reflectors tae harness solar energy continuously, contributin tae net-zero goals. Furthermair, crystals grown in space cuid yield improved drugs, sic as insulin that is nine times mair effective, significantly enhancin the lives o diabetic patients.

Lookin aheid, Dr. Bailet an his team are sikkin fundin tae support the first demonstration o their technology in space. They are committed tae ensurin that future manufacturin projects disnae exacerbate the growin issue o space debris. This pioneerin wark is backed by fundin fae the University o Glesga’s Glesga Knawledge Exchynge Fund an the EPSRC Impact Acceleration Accoont, alangside support fae the UK Space Agency.

The daw o space manufacturin is on the horizon, an wi it comes the promise o a new era in technology an sustainability ayont oor planet.